ZChek F18W Distributors In Mumbai

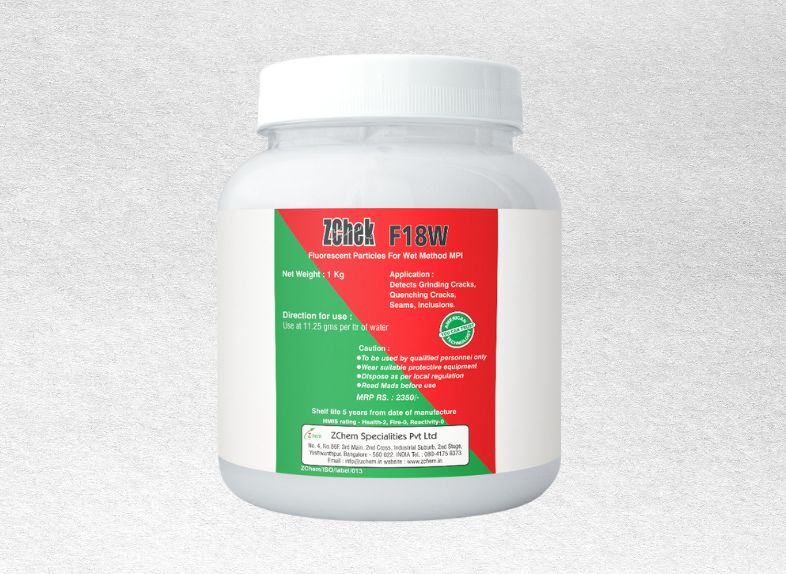

Better Water-Based Fluorescent Magnetic Particle Powder: ZChek F18W

URSA Associates provides Rochem ZChek F18W, an exceptional water-based magnetic particle powder distinguished by its brown hue that fluoresces vivid yellow-green under ultraviolet light. Engineered with ultra-high sensitivity particles, it targets minute flaws in ferromagnetic materials with precision. Utilizing cutting-edge encapsulation technology, ZChek F18W exhibits remarkable traits crucial for achieving heightened sensitivity in fluorescent magnetic particle inspections. These attributes include elevated permeability, minimal retentivity, superior mobility, and uniform particle dispersion. Moreover, F18W incorporates unique additives ensuring optimal particle mobility in water and preventing flash rusting of inspected components.

Features

- Ultra-High Sensitivity:Sensitivity: Designed to detect even the smallest discontinuities, this formulation contains ultra-sensitive particles

- Bright Fluorescence:Under UV light, fluoresces bright yellow-green, giving off a clear signal.

- Water-Based: Its water-based magnetic particle powder design makes it user-friendly and adaptable.

- Encapsulation Technology:Makes use of cutting-edge encapsulation to achieve ideal qualities, such as low retentivity and high permeability.

- Prevents Flash Rusting: During the inspection process, certain additives keep parts from flash rusting.

Applications

- Applications Following Secondary Processing: Perfect for component inspections carried out following secondary processing.

- Castings: Suitable for checking castings for possible flaws.

- Finding Tiny Discontinuities:Made especially to find minuscule discontinuities in ferromagnetic materials.

- Applications:Suitable for a broad variety of ferromagnetic metals.

- Forging:Useful for checking for potential discontinuities in forgings.

- High Volume Testing:Appropriate in situations when a high volume of testing is necessary.

- In-Service Inspections:Designed to be carried out while a component is still in use.

- Iron Alloys, Nickel Alloys: Relevant to many types of iron and nickel alloys.

- Smooth Surface Finish: This type of surface inspection works well for smooth surfaces.

- Stamped Parts, Steel: Suitable for Steel Stamped Parts and other Steel Components inspections.

Examples of Defects

- Cracks in fatigue

- grating fractures

- Contains

- Pauses

- Crack quenching

- Seams

- Shrink cracks

- Weeping

- flaws in welding

Certifications / Observance

- Complies with the American Society of Mechanical Engineers' Boiler and Pressure Vessel Code (ASM E B & PV Code, Sec. V).

- AMS 3044:Conforms to specifications outlined in AMS (Aerospace Material Specification) standards.Complies with the requirements stated in the standards known as AMS (Aerospace Material Specification).

- ASTM E 1444/E 1444M:Complies with ASTM requirements for evaluating fluorescent magnetic particles.

- ASTM E 709: Magnetic particle inspection that complies with ASTM requirements.

- EN ISO 9934-2: Meets European requirements for the inspection of magnetic particles.

ZChek F18W: Experience High Sensitivity

If you want to increase the sensitivity of your fluorescent magnetic particle inspections, go with ZChek F18W. This powdered magnetic particle based on water is designed to detect defects in ferromagnetic materials with accuracy.

Enquiry Now